Our Product

Fly Ash Bricks Making Machine

Automatic Fly Ash Brick Making Machine · Automatic Fly Ash Brick Plant · Automatic Concrete Bricks and Block Making Plant .

- Overall Plant Dimension : 60*40*18

- Conveyor Belt : 25 Feet

- Pan Mixer : 72 Inch

- Hydraulic Oil Capacity : 300 Ltr

- Hydraulic Pressure : 150 _ 180 Tonnage

lift Mixer Machine

We are indulged in offering the finest quality Cement Mixer Machine. Leading Manufacturer of concrete mixer machine.

- Press Structure : 1 Nox (Heavy Duty)

- Working Hight : 60 ft.

- Electric Motor : 10 HP, 3 Phase

- Mix Capacity : 200 Ltr.

- Drum Speed : 20-25 RPM.

Slab Trolly

Slab trolley is also called a tilting bucket trolley. Slab trolley is to carry concrete on slab is also used during excavation of plinth to carry the material. The material from the lift is directly dropped into the trolley .

- Capacity : 100 to 150 Kg

- Material: Mild Steel

- Wheels : Cast Iron Heavy Duty With Ball Bearing

- Mobility : Tilting Bucket Rotates Through 180 Degrees

VIBRATING TABLE

Vibrating tables are designed to settle and compact dry bulk materials in various types of containers. Their application provides either a sizable increas.

- With 2 HP Motor

- Vertical Vibration Type

- Maintain Amplitude at High Frequency

- Mounting Pad for Better Vertical Vibration and Lesser Noise

.jpg)

Mixer (Model - RM800)

Professional service of Mixer (Model - RM800) uses specialized, project management techniques to oversee the planning, design.

- With 10 HP 3 Phase

- Hopper Capacity : 800kg

- Water Tank : 225 Literl

- Water Pump : 1 HP, 3 Phase

- Electronic Control Panel : Semi Automatic

hydrulics Hopper Mixer Machine

The hydraulic press brick machine are also equipped with exceptional safety traits to ensure that they pose minimal risks associated with operations.

- Power Consumption

- Main Press : 7.5 HP

- Capacity : 1/1.5 Bag

- Conveyor : 1.5 HP

- Total : 16.5 HP

Semi Automatic Fly Ash Bricks Making Machine

Our Semi Automatic Fly Ash Bricks Making Machine is a highly efficient and versatile solution designed to cater to the needs of brick manufacturers seeking a balance between automation and manual control. This machine is meticulously crafted to deliver consistent and high-quality fly ash bricks, empowering your brick production process with ease and precision.

- Power Consumption

- Main Press : 7.5 HP

- Block Per Stroke 9*4*3 (Inch) : 4 Nos.

- Cycle Time : 18-20 Sec

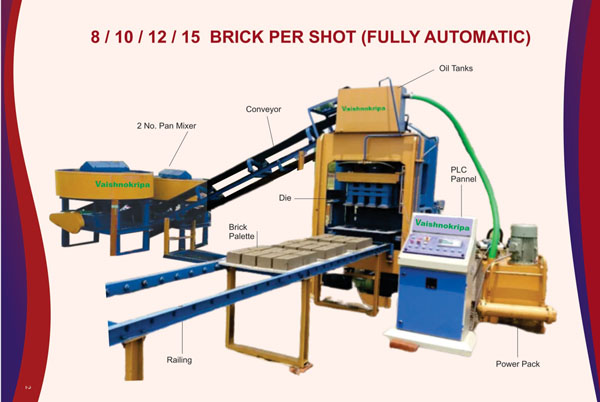

Fully Automatic Fly Ash Bricks Making Machine

Our Fully Automatic Fly Ash Bricks Making Machine represents the pinnacle of modern brick manufacturing technology. With cutting-edge automation, precision engineering, and user-friendly features, this machine takes brick production to a whole new level of efficiency and productivity. Say goodbye to manual labor and embrace the seamless automation of our state-of-the-art machine.

- Power Consumption

- Main Press : 10 HP

- Brick Per Stroke9*4*3 (Inch) : 8/10/12/15 Nos.

- Cycle Time : 18-20 Sec

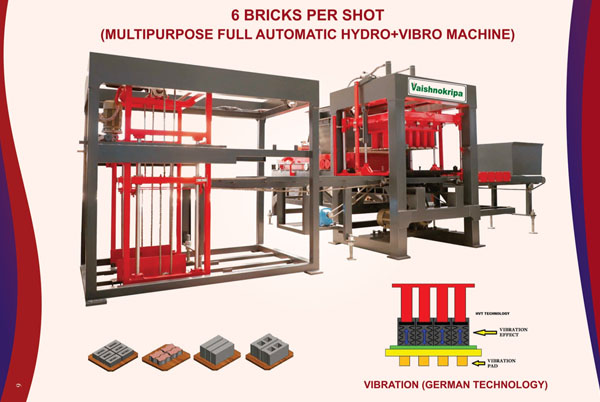

Automatic Hydro & Vibro Fly Ash Bricks Making Machinee

Our Full Automatic Hydro & Vibro Fly Ash Bricks Making Machine is a state-of-the-art solution designed to revolutionize the brick manufacturing process. With cutting-edge technology and precision engineering, this machine ensures seamless and efficient production of high-quality fly ash bricks.

- Power Consumption

- Main Press : 31.5 HP

- Brick Per Stroke9*4*3(Inch): 6

- Cycle Time : 15-20 Sec

- 4 Stroke per minute : 24 Bricks/ Minute

About Fly Ash Machine Product

Fly ash Bricks "Eco friendly product" is a Pulverised ash brick (PAB) technology is a process of converting industrial waste materials into quality building materials. At present, the technology is well established in converting thermal power plant waste into quality bricks. These bricks are machine made & uniform in shape and size, therefore, here is no variation in size of the bricks & require less mortar in. The thickness of plaster can be reduced substantially.

Fly ash is used for the manufacturing of bricks and these bricks are also called fly ash bricks. These are environmental friendly and are also economical when it comes to finances as compared to various other building products. Many builders use the fly ash bricks because of their comparative strength than the conventional bricks.

3,218

Employees

6,154

Projects